Search

-

Corrosion resistant and non magnetic steel

- Ferritic and martensitic steels, incl. precipitaion hardening steel

- Austenitic steels

- Duplex and super duplex stainless steels

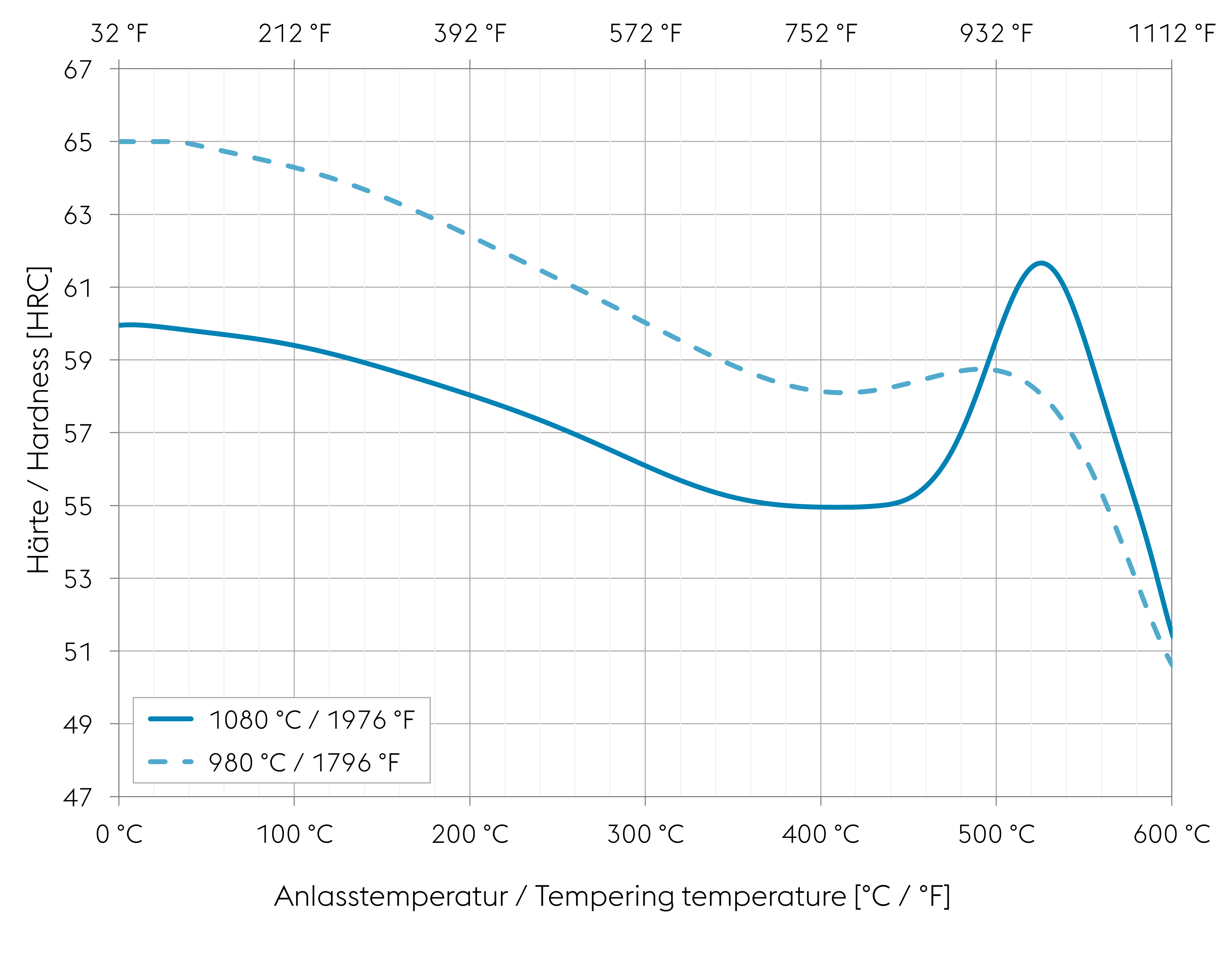

BÖHLER K105 is a 12% ledeburitic chromium steel and corresponds to material number 1.2601 (X165CrMoV12). This commonly used tool steel is highly resistant to abrasive wear. Compared to modern cold work tool steels, BÖHLER K105 has the advantage of simple heat treatment with lower hardening temperatures and single tempering. The improved tempering resistance of BÖHLER K105 compared to the conventional tool steel 1.2080 also enables nitriding treatment of tools.

| Compressive strength | Dimensional Stability in heat treatment | Toughness | Wear resistance abrasive | Wear resistance adhesive |

|---|---|---|---|---|

|

|

|

|

|

|

| SEL | UNS | EN | AISI | GOST |

|---|---|---|---|---|

| 1.2601 | ~T30402 | X165CrMoV12 | ~D2 | ~Ch12MF |

| C | Si | Mn | Cr | Mo | V | W | |

|---|---|---|---|---|---|---|---|

| 1.60 | 0.35 | 0.30 | 11.50 | 0.60 | 0.30 | 0.50 |

Information on Long Products ) Presented data refer exclusivly to long products. Please observe the detailed explanations at the end of the data sheet (pdf).